I spent a lot of time researching thermal insulation online and found a myriad of approaches and opinions. I decided against standard fiberglass batt (the pink stuff used in houses), as it would break down under the stresses of driving and probably give me mesothelioma. I decided against the eco-friendly variant, cotton batt made from recycled jeans, because vans tend to be humid environments and I didn’t want to have mold issues. I settled on rigid polyisocyanurate foam, which has a very high R value for its thickness.

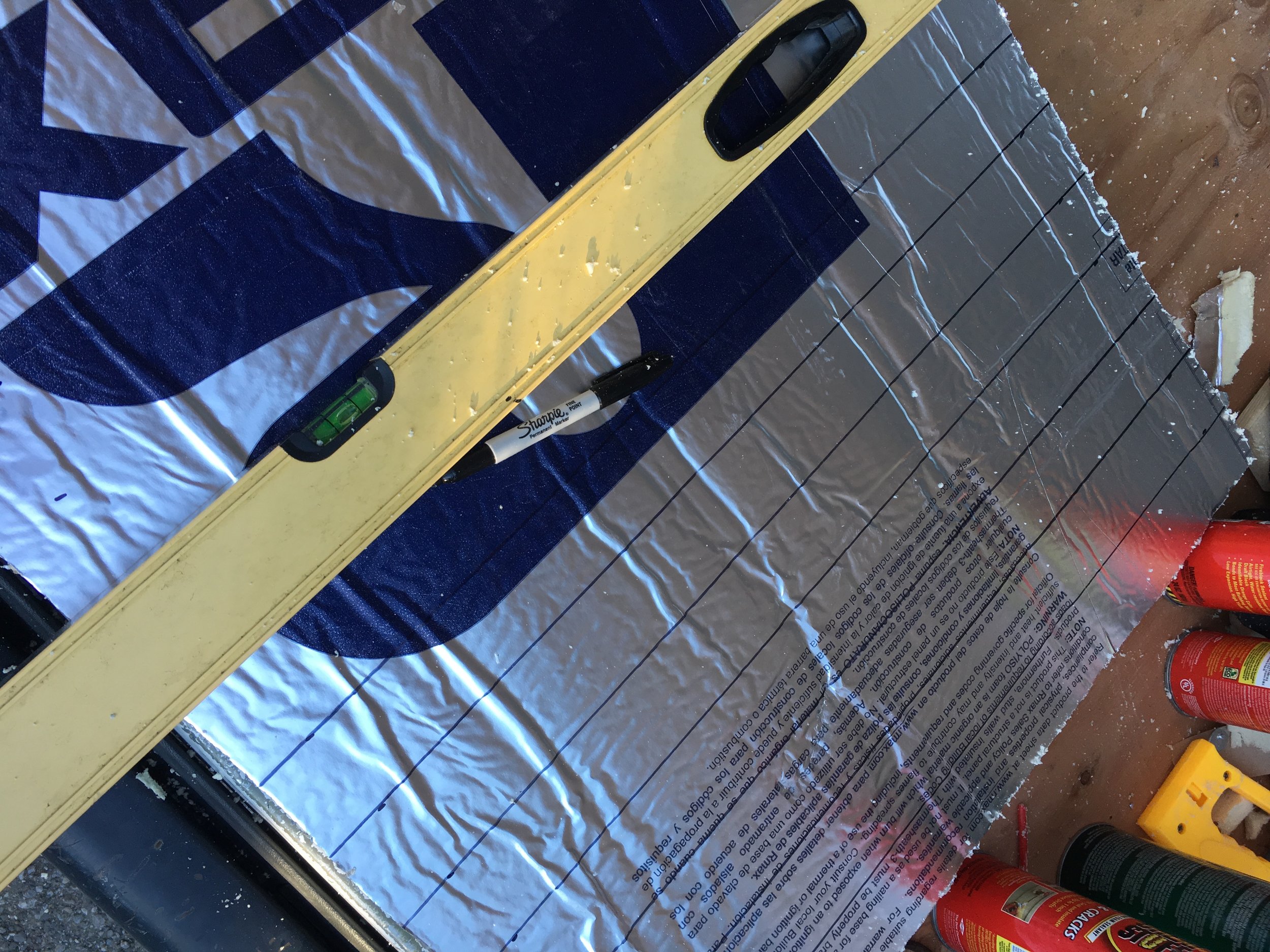

The polyiso foam comes in 4’ x 8’ sheets, just like plywood, which meant that I had to make a lot of templates again in order to fit it to the walls and ceiling. The foam posed another issue - it was rigid, whereas my walls and ceiling were curved. I employed a technique called “kerfing”, wherein the foam is sliced almost entirely through at regular intervals in order to flex evenly and approximate a smooth curve. After kerfing and taping the insulation in place, I filled in the cracks with more Great Stuff spray foam and little cut off bits of polyiso foam.